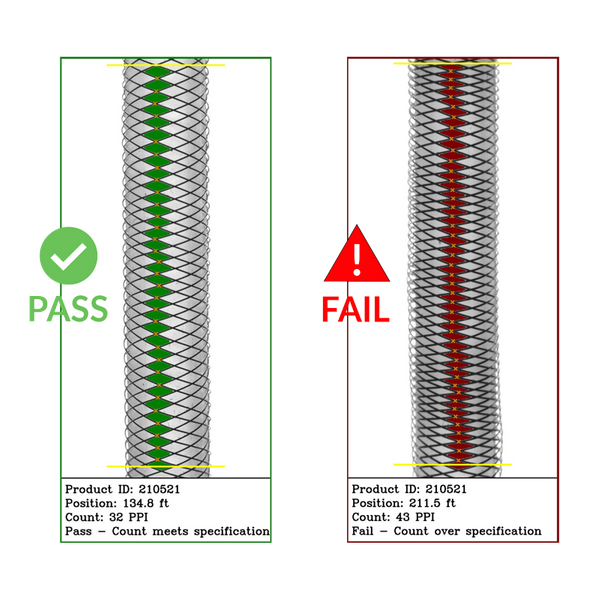

Taymer’s braid inspector (BX1100) measures braid density (also known as pick count or picks per inch (PPI)) on braided catheters, stents, cables, and other braided products for quality assurance and reliable automated production.

The braid inspector uses custom-designed lighting, digital imaging to enable real-time inspection. The digital inspection images are enhanced, magnified and displayed on a monitor to visually confirm the braids, target position and see any potential errors.

The BX1100 can be mounted inline on horizontal or vertical braiders for automatic inspection, or work offline as a tabletop unit for fast and easy inspection by the operator.

Features

- Braid Inspector is designed to measure density of count picks within a desired length

- High resolution cameras and custom-designed lighting system increases the accuracy the braid inspection

- Digital images are captured and analyzed automatically by the software to give you results in real time

- Can be used in a continuous inline or offline configuration

- Capture system can be mounted inside a horizontal or vertical braider enclosure

- Can be integrated with the braider to control production and improve your process

- Small footprint, simple set-up and easily handled by operators